BAKERY SHORTENING PLANT

VAAPF ENGINEERS PVT LTD

8, Laxmi Industrial Estate, Ground Floor, Penkarpada Road, Mira, Thane District, Maharashtra, India.

Mumbai, Maharashtra 401104

India

ph: +91 22 28964151

fax: +91 22 28964151

alt: +91 9820216099 / 9869086851

info

BAKERY SHORTENING PLANT ESSP 100V

THE BAKERY SHORTENING PLANT COMPRISES THE FOLLOWING

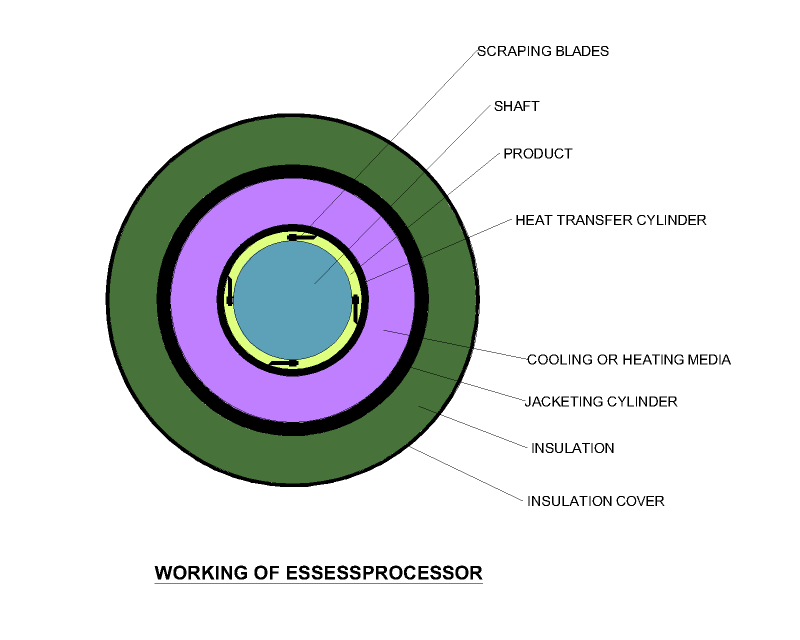

1. ESSESSPROCESSOR

THIS IS A SCRAPED SURFACE HEAT EXCHANGER WITH SPECIAL OUTSIDE SERRATED CYLINDER FOR

SUPERIOR HEAT TRANSFER EFFICIENCY. THE SPECIAL DESIGN OF THIS CYLINDER PREVENTS ANY

BUILD UP OF OILS USED WITH THE REFRIGERENT AROUND THE CYLINDER. ESSESSPROCESSOR

FORMS HEART OF THE PLANT WITH SUPERIOR HEAT TRANSFER PERFORMANCE CAPABLE OF

HANDLING A WIDE RANGE OF VISCOUS PRODUCTS. THIS PLANT CAN BE CONVENIENTLY USED IN THE

CONTINUOUS CLOSED PROCESSING OF ANY PUMPABLE FLUID OR SLURRY FOR COOKING, COOLING,

MIXING, CRYSTALLIZING, SLUSH FREEZING, PLASTICIZING, POLYMERIZATION, HEATING AND ASEPTIC

PROCESSING. IN FACT, THIS EQUIPMENT HAS REPLACED THE CONVENTIONAL TUBULAR AND PLATE

TYPE HEAT EXCHANGERS IN FOOD, CHEMICAL, PHARMACEUTICAL, PETROLEUNM AND ALLIED

INDUSTRIES.

THE CONSTRUCTION OF THE ESSESSPROCESSOR IS SUCH THAT INSIDE THE CHILLING CYLINDER A

CONCENTRICALLY MOUNTED SHAFT REVOLVING ALONG WITH ITS SCRAPING BLADES,

CONTINUOUSLY SCRAPE THE INSIDE SURFACE OF THE CHILLING CYLINDER. THE PRODUCT FLOWS

THROUGH THE ANNULAR SPACE FORMED BETWEEN THE SHAFT AND THE CHILLING CYLINDER. HEAT

TRANSFER MEDIUM RUNS THROUGH THE JACKET OF THE CHILLING CYLINDER WHICH IS SUITABLY

INSULATED AND CLADDED WITH STAINLESS STEEL SHEET TO ENSURE UTMOST HYGENIC CONDITION.

THE REVOLVING SHAFT INSIDE THE CHILLING CYLINDER WHILE REVOLVING CONTINUOUSLY, SCRAPE

THE PRODUCT FILM FROM THE CHILLING CYLINDER WALL THEREBY ENSURING AN EXCELLENT HEAT

TRANSFER AND HOMOGENOUS AND UNIFORM PRODUCT. THE HEAT TRANSFER TUBE IS MADE OUT

OF AISI 304 STAINLESS STEEL MATERIALS AND THE JACKET OUT OF CARBON STEEL COATED WITH

SUITABLE CORROSION RESISTANT PAINTS. THE NUMBER OF CHILLING CYLINDERS DEPENDS UPON

THE NATURE AND QUANTITY OF PRODUCT TO BE PROCESSED. OUR STATNDARD MODEL WITH THREE

NUMBERS OF CHILLING CYLINDERS WILL GIVE AN OUTPUT OF 2.250 METRIC TONS PER HOUR OF

SHORTENING OR 1.500 METRIC TONS PER HOUR OF TABLE MARGARINE OR O.750 TONS PER HOUR

OF PUFF PASTRY MARGARINE WITH A TEMPERATURE DIFFERENCE OF APPROXIMATELY 20 TO 25

DEGREE C. THE PRESSURE COMPONENT OF THE PLANT IS MADE IN ACCORDANCE WITH PRESSURE

EQUIPMENT DIRECTIVE (PED) 97/23/EC.ASME SEC VIII DIV.1. THE SATNDARD SCRAPER SYSTEM IS OF

FLOATING TYPE POLYMER BALDES FIXED TO THE SHAFT IN FOUR ROWS.

THE COOLING MEDIA CAN BE NH3 / FREON.

WE CAN ALSO OFFER PLANT WITH DIFFERENT TYPE OF MATERIALS OF CONSTRUCTION WITH

SMALLER OR HIGHER PRODUCTION CAPACITY CAPABLE OF WORKING AT DIFFERENT

WORKING PRESSURES AND TEMPERATURES.

2. CRYSTAL DISTRIBUTION CUM STABILIZER

HORIZONTALLY MOUNTED AND SEQUENTIALLY CONNECTED TO THE ESSESSPROCESSOR ABOVE.

THERE ARE TWO ROWS OF FIXED PINS WITH A CONCENTRIC SHAFT CARRYING PINS IN A HELICAL

ARRANGEMENT WHICH INTERMESH WITH FIXED PINS WHILE ROTATING. THE SHAFT IS DRIVEN

THROUGH A GEAR BOX AND A SUITABLE DRIVE MOTOR. FURTHER THIS DRIVE IS PROVIDED WITH A

SUITABLE VARIABLE SPEED FREQUENCY DRIVE FOR HANDLING A WIDE VARIETY OF MARGARINE AND

BAKERY SHORTENING PRODUCTS UNDER HIGH OR LOW PRESSURE AT VARIABLE SPEEDS. ALL

PRODUCT CONTACT PARTS ARE MADE OUT OF AISI 304 STAINLESS STEEL MATERIALS AND

MECHANICAL SEALS ARE SEMI-BALANCED WITH TUNGSTEN CARBIDE/SILICON CARBIDE WEARING

RINGS.

3. TRIPLEX RECIPROCATING PLUNGER PUMP

TRIPLEX MODEL SINGLE ACTING RECIPROCATING PLUNGER PUMP IS USED FOR FEEDING OF THE

PRODUCT TO THE SYSTEM. ALL PRODUCT CONTACT PARTS ARE AISI 304 / 316 STAINLESS STEEL

MATERIALS. THE PUMP IS DRIVEN BY A SUITABLE DRIVE MOTOR CONNECTED WITH A VARIABLE

FREQUENCY DRIVE FOR RUNNING THE PUMP AT DIFFERENT SPEED TO HANDLE A WIDE VARIETY OF

MARGARINE AND BAKERY SHORTENING PRODUCTS AT HIGH OR LOW PRESSURE AT VARIABLE SPEEDS.

THE PRODUCT COMPARTMENT IS JACKETED FOR PASSING OF HEATING MEDIA DURING PRODUCTION

STOPPAGE.

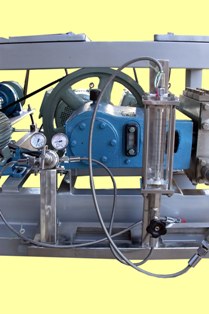

4. NITROGEN PURGING SYSTEM

WHEN A PARTICULAR PRODUCT REQUIRES NITRGEN INFUSION THIS SYSTEM WILL COME INTO

FORCE. THIS SYSTEM CONSISTS OF PRESSURE REGULATING VALVE FOR REGULATING LINE PRESSURE

WITH TWO NUMBER OF GAUGES FOR READING THE LINE AS WELL AS CYLINDER PRESSURE. THIS

SYATEM HAS FLOWMETER WITH A REGULATING VALVE FOR ADJUSTING THE INFLOW OF QUANTITY

OF GAS IN THE PRODUCT. THE MATERIAL OF CONSTRUCTION OF CONTACT PARTS WILL BE AISI 304

STAINLESS STEEL.

NITROGEN GAS PURGING ARRANGEMENT

5. INTERCONNECTING PIPELINE

THE INTERCONNECTING PIPELINE FROM PUMP TO ESSESSPROCESSOR TO CRYSTALIZER TO FILLING

POINTS IS MADE UP OF AISI 304 STAINLESS STEEL MATERIALS, SUITABLY JACKETED FOR PASSING OF

HEATING MEDIA LIKE STEAM OR HOT WATER. THIS WILL REDUCE THE RESTART TIME OF THE PLANT

WHEN THERE IS STOPPAGE OF PRODUCTION DUE TO POWER FAILURE OR END OF THE BATCH WHICH

WILL REDUCE THE PRODUCTION DOWNTIME TO A MINIMUM LEVEL. WE HAVE PROVIDED CONTROL

VALVES, TEMPERATURE SENSORS, TEMPERATURE GAUGES, SAMPLING COCKS,QUICK RELEASE

COUPLINGS ETC. FOR ENABLING EFFORTLESS AND QUICK OPERATION OF THE PLANT.

6. CONTROL PANEL

THIS CONTROL PANEL NOT ONLY ENABLES SMOOTH AND TROUBLE FREE OPERATION BUT ALSO

ENSURES SAFE HANDLING OF THE PLANT. THE UNIQUE DESIGN FEATURE OF THE CONTROL PANEL

PREVENTS MISHANDLING OF THE PLANT THEREBY AVOIDING COSTLY DAMAGES. THE PLANT DOES

NOT START UNLESS TEMERATURE OF THE PRODUCT AT SPECIFIED LOCATIONS IS BELOW THE SET

TEMPERATURE LIMIT. AT THE SAME TIME THE PLANT DOES NOT STOP EVEN IF THE TEMPERATURE

OF THE PRODUCT GOES BELOW THE SET TEMPERATURE LIMIT ONCE THE PLANT STARTS. THIS

SAFETY FEATURE AVOIDS DAMAGES TO THE COSTLY COMPONENTS LIKE MECHANICAL SEALS,

BEARINGS, DRIVE SHAFTS AND SCRAPING BLADES WHEN THE PRODUCT INSIDE THE EQUIPMENT AND

PIPELINE IS SOLID DUE TO POWER FAILURE OR PRODUCT CHANGE OVER.

CONTROL PANEL | |||||||||

Copyright 2011 Vaapf Engineers. All rights reserved.

VAAPF ENGINEERS PVT LTD

8, Laxmi Industrial Estate, Ground Floor, Penkarpada Road, Mira, Thane District, Maharashtra, India.

Mumbai, Maharashtra 401104

India

ph: +91 22 28964151

fax: +91 22 28964151

alt: +91 9820216099 / 9869086851

info